Ọcha Dị Ọcha Bi Powder Metal Bismuth Powder

Nkọwa ngwaahịa

Bismuth ntụ ntụ bụ ntụ ntụ ọla ọcha na-acha ntụ ntụ nwere ntụ dara dara.Enwere ike imepụta ya site na usoro nzọpịa igwe, usoro egwe ọka, na usoro atomization nke usoro dị iche iche.Ngwaahịa ahụ nwere ịdị ọcha dị elu, nha urughuru edo, ụdị okirikiri, mgbasa ozi dị mma, okpomoku oxidation dị elu na oke mbelata nke sintering.

Nkọwapụta

| Aha ngwaahịa | Bismuth metal ntụ ntụ |

| Ọdịdị | ụdị ntụ ntụ ntụ ntụ |

| Nha | 100-325 ntupu |

| Usoro ihe omimi | Bi |

| Ibu molekụla | 208.98037 |

| Ebe Na-agbaze | 271.3C |

| Ebe esi nri | 1560±5 ℃ |

| CAS Mba. | 7440-69-9 |

| EINECS Mba. | 231-177-4 |

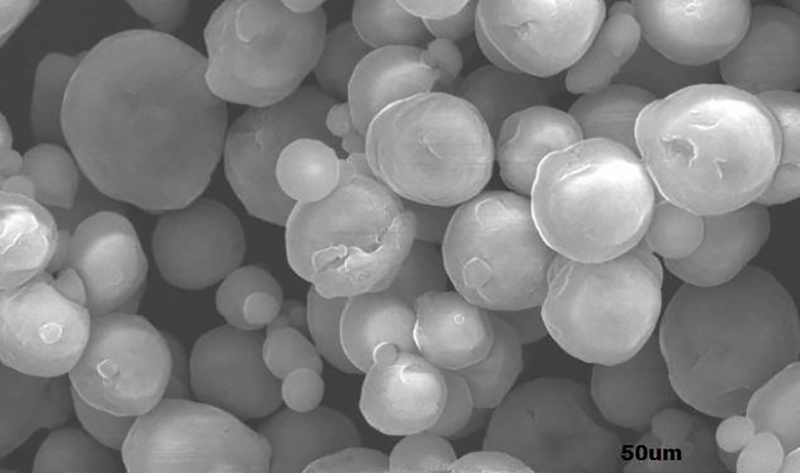

SEM

Ngwa

1. Metal nano lubricating mgbakwunye: Tinye 0.1 ~ 0.5% nano bismuth ntụ ntụ na griiz na-emepụta ihe nkiri na-edozi onwe ya na nke na-agwọ onwe ya n'elu akụkụ nke esemokwu n'oge usoro esemokwu, nke na-eme ka arụmọrụ nke griiz dịkwuo mma;

2. Ihe mgbakwunye metallurgical: a pụrụ iji ntụ ntụ bismuth mee ihe dị ka ihe mgbakwunye maka nkedo ígwè, ígwè na aluminom alloys iji meziwanye ihe nkwụsị n'efu nke alloys;

3. Ihe ndọta: bismuth nwere obere akụkụ ikuku neutron thermal thermal absorption cross section, ala na-agbaze na ebe a na-esi esi elu, ya mere enwere ike iji ya dị ka ihe na-ekpo ọkụ na-ekpo ọkụ na ndị na-emepụta ngwá agha nuklia;

4. Ngwa ndị ọzọ:

A na-eji ya eme ihe na ngwaahịa bismuth alloy dị iche iche, ụgwọ nyocha mmanụ, ndị na-ere ọkụ dị ala, ndị na-ahụ maka plastik, wiil electroplating, diski na-egweri, mma na-amụba, na nkwadebe nke ihe semiconductor dị elu na-adị ọcha na ogige bismuth dị ọcha.

Usoro njikwa mma

Huarui nwere usoro njikwa mma siri ike.Anyị na-anwale ngwaahịa anyị mbụ mgbe anyị mechara mmepụta anyị, anyị na-anwalekwa ọzọ tupu nnyefe ọ bụla, ọbụna sample.Ma ọ bụrụ na ịchọrọ, anyị ga-achọ ịnakwere ndị ọzọ iji nwalee.N'ezie ọ bụrụ na-amasị gị, anyị nwere ike ịnye gị sample iji nwalee.

Sichuan Metallurgical Institute na Guangzhou Institute of Metal Research kwadoro ogo ngwaahịa anyị.Ogologo oge imekọ ihe ọnụ na ha nwere ike ịzọpụta ọtụtụ oge ule maka ndị ahịa.