silicon carbide ntụ ntụ

Nkọwa ngwaahịa

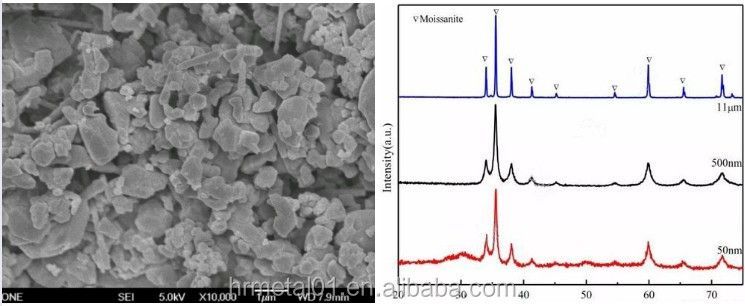

Ihe mejupụtara kemịkalụ nke silicon carbide ntụ ntụ bụ nke mejupụtara ihe abụọ, Si na C, nke oke Si na C bụ 1: 1.Na mgbakwunye, silicon carbide nwere ike ịnwe obere ihe ndị ọzọ, dị ka Al, B, P, wdg, ọdịnaya nke ihe ndị a ga-enwe mmetụta ụfọdụ na arụmọrụ nke silicon carbide.Silicon carbide ntụ ntụ nwere ọtụtụ ngwa ngwa n'ọtụtụ mpaghara, dị ka eletrọnịkị, ike, ikuku ikuku, ụgbọ ala na ihe ndị ọzọ.N'ebe a na-emepụta ngwá electronic, silicon carbide powder nwere ike iji na-emepụta ngwaọrụ semiconductor, electronic components, wdg N'ebe ike, silicon carbide ntụ ntụ nwere ike iji na-arụpụta nnukwu voltaji ngwaọrụ, transformers, wdg N'ime aerospace ubi. , silicon carbide ntụ ntụ nwere ike iji na-emepụta ihe nhazi ihe dị elu nke okpomọkụ, ngwá ọrụ avionics, wdg N'ime ụgbọ ala ụgbọ ala, silicon carbide powder nwere ike iji mepụta akụkụ akpaaka, engines na ihe ndị ọzọ.

Nkọwapụta

| nkọwapụta silicon carbide sic ntụ ntụ maka nonabrasive | ||||

| Ụdị | Ngwakọta kemịkalụ ntụaka (%) | Nha (mm) | ||

| SiC | FC | Fe2O3 | ||

| TN98 | ≥98.00 | <1.00 | <0.50 | 50 ~ 0 |

| TN97 | ≥97.00 | <1.50 | <0.80 | 13 ~ 0 |

| TN95 | ≥95.00 | <2.50 | <1.00 | 10 ~ 0 |

| TN90 | ≥90.00 | <3.00 | <2.50 | 5 ~ 0 |

| TN88 | ≥88.00 | <3.50 | <3.00 | 0,5-0 |

| TN85 | ≥85.00 | <5.00 | <3.50 | 100F |

| TN60 | ≥60.00 | <12.00 | <3.50 | 200F |

| TN50 | ≥50.00 | <15.00 | <3.50 | 325F |

Ngwa

Usoro njikwa mma

Huarui nwere usoro njikwa mma siri ike.Anyị na-anwale ngwaahịa anyị mbụ mgbe anyị mechara mmepụta anyị, anyị na-anwalekwa ọzọ tupu nnyefe ọ bụla, ọbụna sample.Ma ọ bụrụ na ịchọrọ, anyị ga-achọ ịnakwere ndị ọzọ iji nwalee.N'ezie ọ bụrụ na-amasị gị, anyị nwere ike ịnye gị sample iji nwalee.

Sichuan Metallurgical Institute na Guangzhou Institute of Metal Research kwadoro ogo ngwaahịa anyị.Ogologo oge imekọ ihe ọnụ na ha nwere ike ịzọpụta ọtụtụ oge ule maka ndị ahịa.