Mgbakwunye nrụpụta igwe anaghị agba nchara ntụ ntụ 316l ntụ ntụ maka mbipụta 3d

Nkọwa ngwaahịa

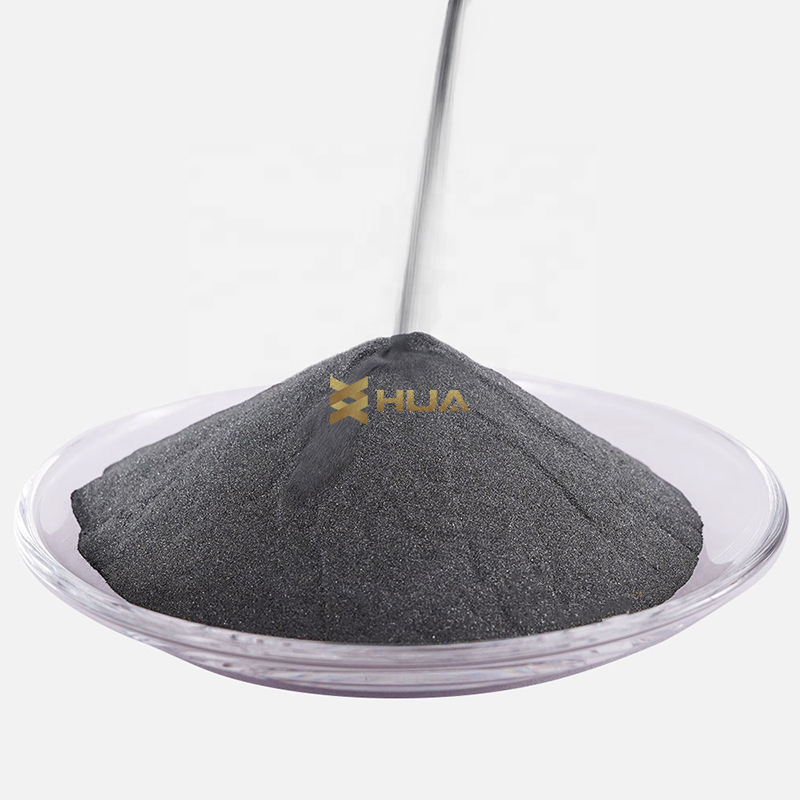

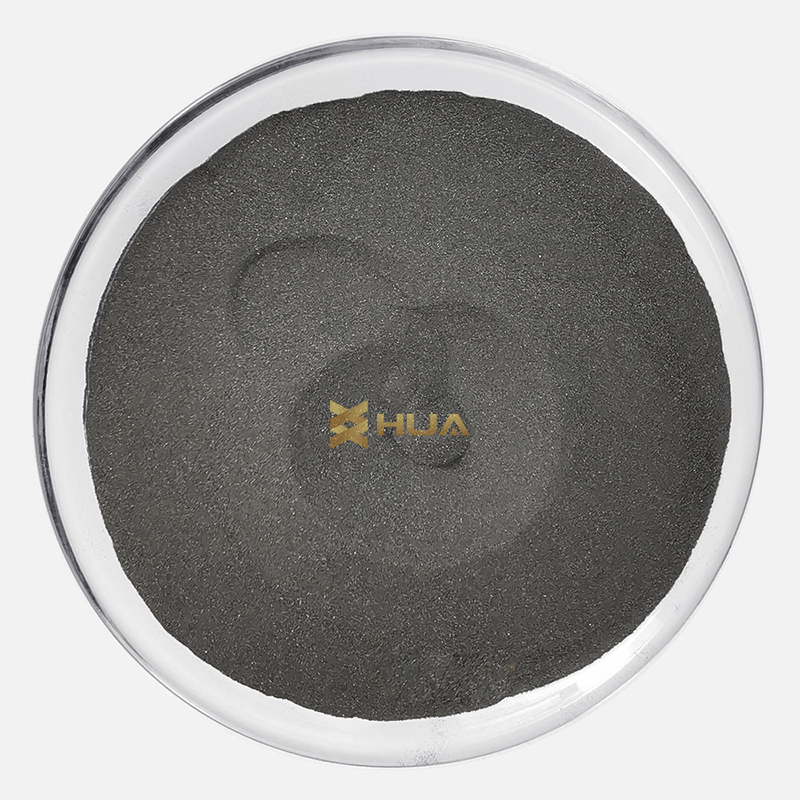

A na-eme ntụ ntụ igwe anaghị agba nchara site na usoro atomization mmiri ma nwee ezigbo nguzogide corrosion na ogologo oge.Igwe anaghị agba nchara ntụ ntụ nwere ọtụtụ ọrụ mmepụta ihe.

Nye ihe dị iche iche nke igwe anaghị agba nchara ntụ ntụ nwere dị iche iche urughuru size.

Dị ka ojiji

1. Hot Isostatic Pressing

2.Metal Injection Molding

3.3D mbipụta

4.Thermal spraying

Dị ka usoro mmepụta

1.Water atomization

2.Water gas jikọtara atomization

3.Gas atomization

4.Vacuum atomization

Nkọwa nkọwapụta

| Ngwakọta ntụ ntụ nchara nchara% | |||||||||

| Ọkwa | Cr | Ni | Mo | Nb | Cu | S | P | C | Si |

| 303 | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.15 | ≤1 |

| 304 | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 316 | 16-18 | 10-14 | 2-3 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303L | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304L | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316L | 16-18 | 10-14 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 317L | 18-21 | 12-16 | 3-4 |

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 314 | 24-27 | 18-21 |

|

|

| ≤0.03 | ≤0.04 | ≤0.2 | 1.5 / 2.5 |

| 310 | 24-26 | 19-22 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303LSC | 17-19 | 8-13 |

|

| 2 | 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304LSC | 17-19 | 8-13 |

|

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316LSC | 16-19 | 10-14 | 2-3 |

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410L | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 430L | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 434L | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434LNB | 16-18 |

| 0.75-1.25 | 0.4-0.6 |

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410 | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.25 | ≤1 |

| 420 | 12-14 |

|

|

|

| ≤0.03 | ≤0.04 | 0.25/0.35 | ≤1 |

| 430 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434 | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 440 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | 0.9 / 1.2 | ≤1 |

| 17-4PH | 15-17.5 | 3-5 |

| 0.15-0.456 | 3-5 | ≤0.03 | ≤0.04 | ≤0.07 | ≤1 |

| 15-5PH | 14-15.5 | 3.5-5.5 |

|

| 2.5-4.5 | ≤0.03 | ≤0.04 | <= 0.07 | ≤1 |

Ngwa

Enwere ike iji ntụ ntụ igwe anaghị agba nchara maka spraying thermal, metallurgy powder, powder metallurgy press sintering (PM), injection molding (MIM) sintering filter, wdg, mmiri atomization oxygen ọdịnaya.<4000PPM, atomization gas<1000PPM.

Uru nke HUARUI igwe anaghị agba nchara ntụ ntụ

● Ọbụna ntụ ntụ mejupụtara, obere adịghị ọcha

● Ọkwa dị elu

● Obere ikuku oxygen

● Ọmarịcha usoro

●Njupụta dị elu, njupụta dị elu

● Ntụ ntụ dị obere, obere satịlaịtị ntụ ntụ

Usoro njikwa mma

1.Huarui nwere usoro nlekọta ahụike siri ike.Anyị na-anwale ngwaahịa anyị mbụ mgbe anyị mechara mmepụta anyị, anyị na-anwalekwa ọzọ tupu nnyefe ọ bụla, ọbụna sample.Ma ọ bụrụ na ịchọrọ, anyị ga-achọ ịnakwere ndị ọzọ iji nwalee.N'ezie ọ bụrụ na-amasị gị, anyị nwere ike ịnye gị sample iji nwalee.

2.Our ngwaahịa àgwà na-ekwe nkwa site Sichuan Metallurgical Institute na Guangzhou Institute of Metal Research.Ogologo oge imekọ ihe ọnụ na ha nwere ike ịzọpụta ọtụtụ oge ule maka ndị ahịa.