Co base cobalt dabeere alloy metal ntụ ntụ maka ịgbado ọkụ spraying

Nkọwa ngwaahịa

Cobalt dabeere alloy bụ ụdị alloy na cobalt dị ka isi akụrụngwa, nwere nnukwu ego nke nickel, chromium, tungsten na obere ego nke molybdenum, niobium, tantalum, titanium, lanthanum na ndị ọzọ alloying ọcha, mgbe ụfọdụ nwekwara ígwè.Dị ka ihe mejupụtara nke alloy, ha nwere ike na-mere n'ime ịgbado ọkụ waya, ntụ ntụ maka ike n'elu surfacing, thermal spraying, ịgba ịgbado ọkụ na ndị ọzọ Filiks, nwekwara ike-mere na nkedo na forging akụkụ na ntụ ntụ metallurgy akụkụ.

Nkọwapụta

| Ihe | HR-Co1 | HR-Co6 | HR-Co12 | HR-Co21 |

| HRC | 48 | 38 | 42 | 28 |

| C | 2.4 | 1.15 | 1.4 | 0.25 |

| Cr | 30.5 | 29 | 29.5 | 27.5 |

| Si | 1 | 1.1 | 1.45 | 2 |

| W | 12.5 | 4 | 8.25 | 0.15 |

| Fe | 3 | 3 | 3 | 2 |

| Mo | 1 | 1 | 1 | 5.5 |

| Ni | 3 | 3 | 3 | 2.5 |

| Co | Bal | Bal | Bal | Bal |

| Mn | 0.25 | 0.5 | 1 | 1 |

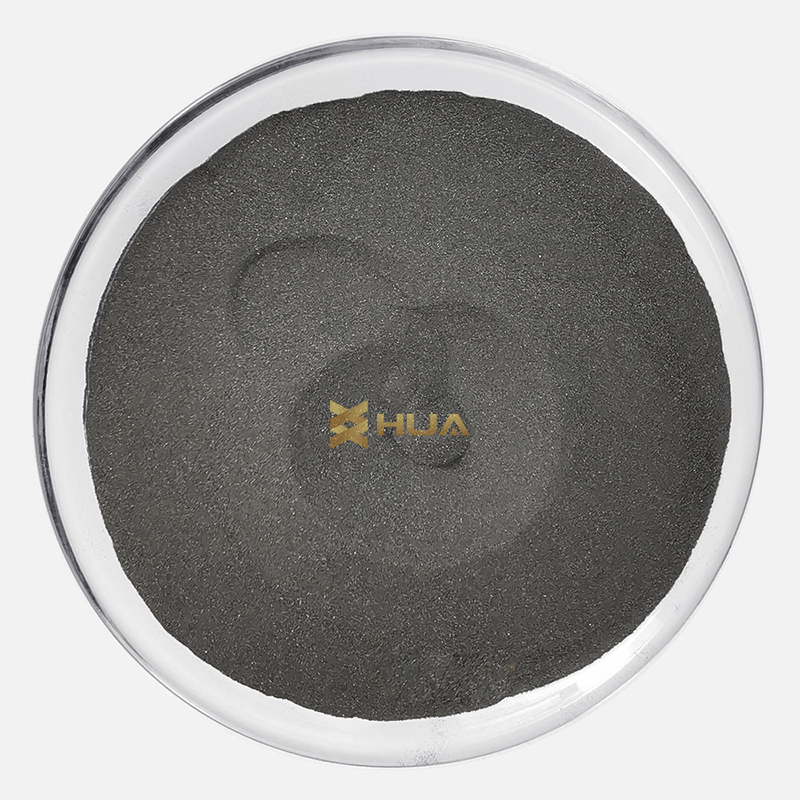

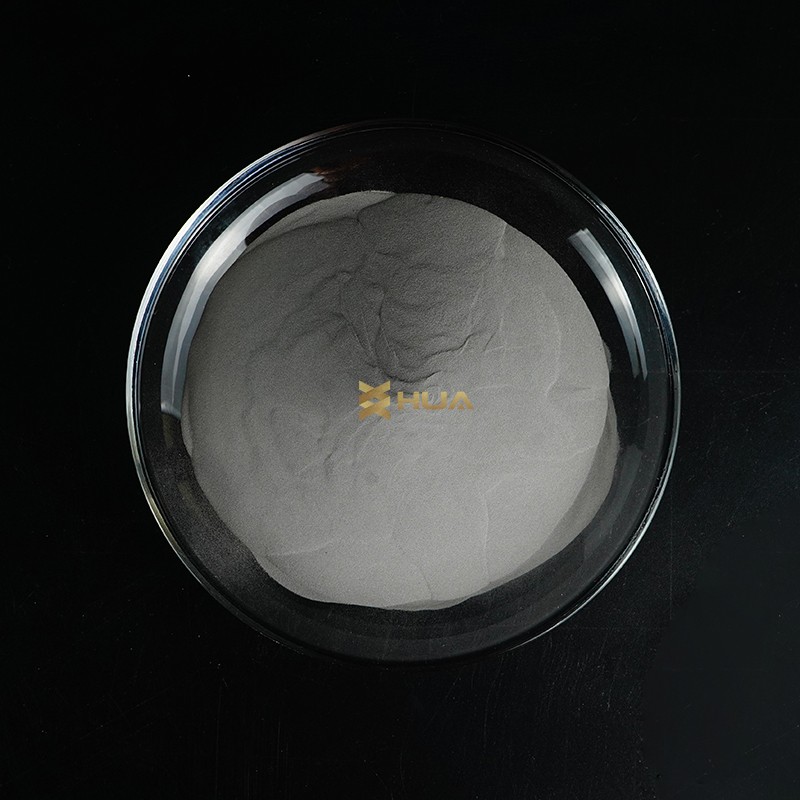

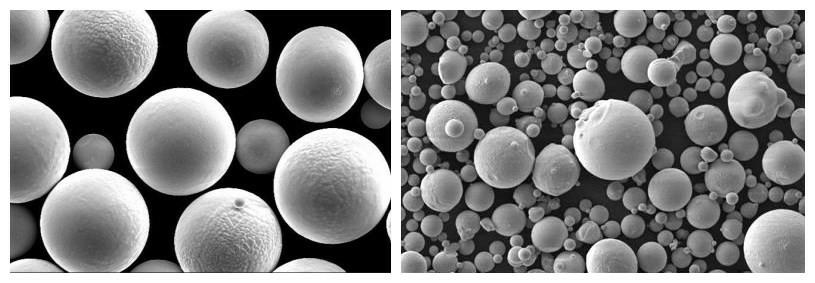

SEM

Ngwa

Alloys dabere na cobalt nwere ike dị elu, ezigbo iguzogide ike ọgwụgwụ ọkụ, corrosion thermal na abrasion, yana weldability dị mma na okpomọkụ karịa 980 ℃.Kwesịrị ekwesị maka injin ụgbọ elu ụgbọ elu, turbine gas ụlọ ọrụ, ụgbọ mmiri gas turbine ndu vane na nozzle guide vane na dizel nozzle wdg.

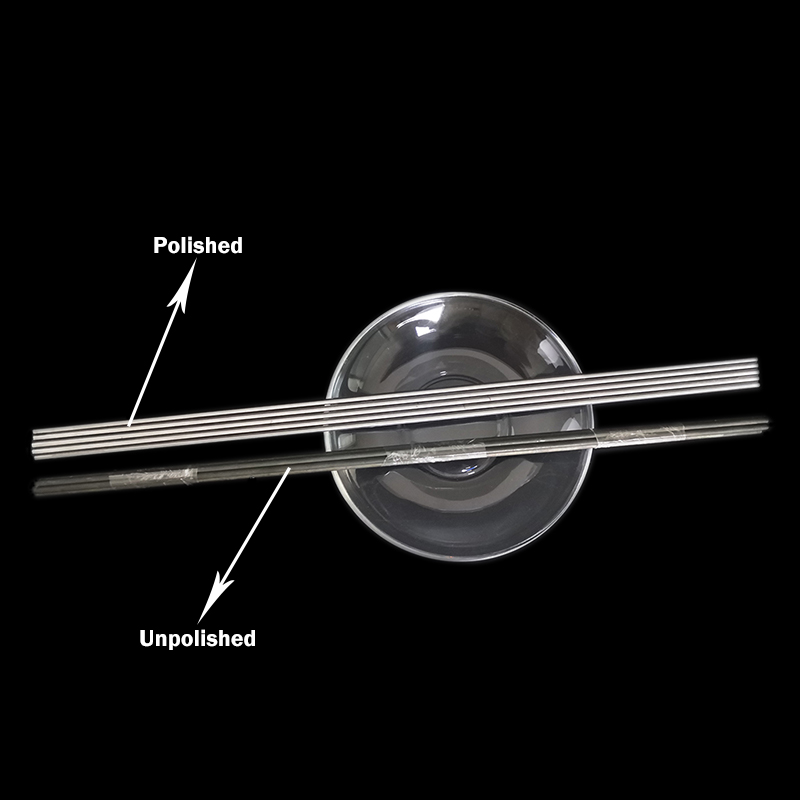

1.Hardfacing

2.Wear na-eguzogide ịgbado ọkụ TIG / MIG

3. Thermal ịgba PTA/HVOF

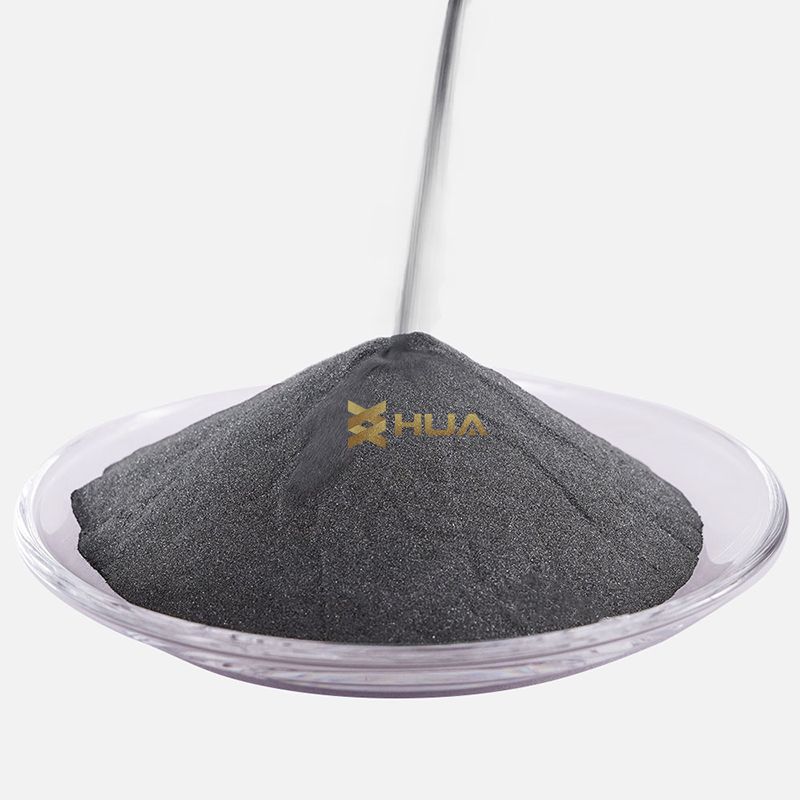

HUARUI cobalt alloy ntụ ntụ uru:

● elu spericity

● elu chemical mejupụtara homogeneity

● njupụta dị elu / ịkụ aka

● Ọdịnaya nsonye dị ala

● Ọdịnaya oxygen dị ala

● High flowability

● Ọkpụrụkpụ n'otu n'otu na obere porosity