carbonyl ígwè ntụ ntụ

Nkọwa ngwaahịa

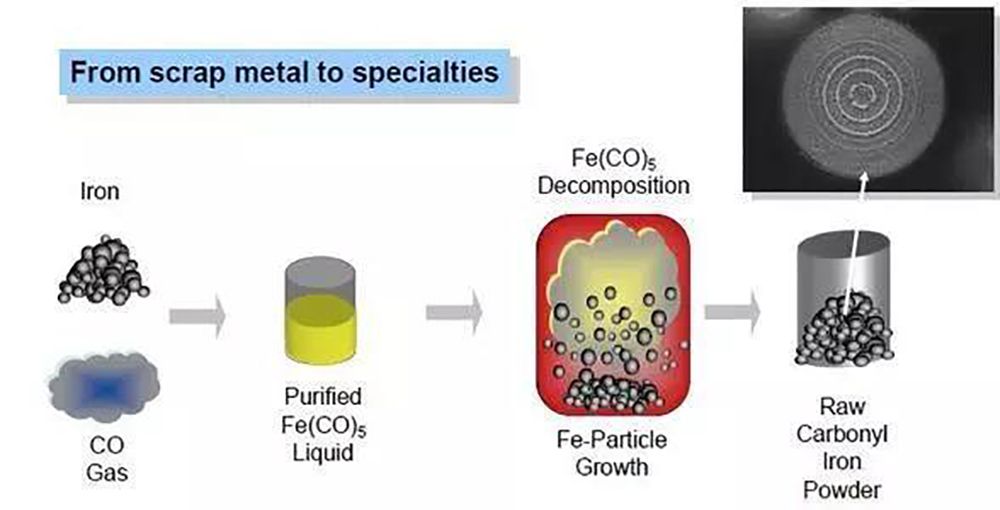

Carbonyl ígwè ntụ ntụ bụ ụdị ultra-mma metal ntụ ntụ, nke nwere àgwà nke ịdị ọcha dị elu, ezigbo mmiri mmiri, mgbasa ozi dị mma, ọrụ dị elu, ihe ndị dị mma electromagnetic, ezigbo ịpị na sintering formability.A na-eji ntụ ntụ carbonyl eme ihe n'ọtụtụ ebe na agha, ngwa elektrọn, kemịkalụ, ọgwụ, nri, ọrụ ugbo na mpaghara ndị ọzọ.Enwere ike ịkwadebe ntụ ntụ Carbonyl n'ụdị dị iche iche dị ka eriri, flake ma ọ bụ bọọlụ dịka ihe achọrọ iji gboo mkpa dị iche iche nke ndị ahịa.

Nkọwapụta

| Ihe | Ngwakọta kemịkalụ | Ngwongwo anụ ahụ | |||||||

| Fe | C | N | O | APP.Njupụta | Pịa njupụta | Ogo urughuru Laser | |||

| ≥% | ≤% | ≥ | ≥ | D10 | D50 | D90 | |||

| HR1-1 | 98 | 0.8 | 0.6 | 0.4 | 2.2 | 4 | 0.5-1.0 | ≤2.0 | 3.0-5.0 |

| HR1-2 | 98 | 0.8 | 0.6 | 0.4 | 2.5 | 3.9 | 0.6-1.5 | 2.0-3.0 | 4.5-8.0 |

| HR1-3 | 98 | 0.8 | 0.6 | 0.4 | 2.5 | 3.8 | 1.0-3.0 | 3.0-5.0 | 5.0-12.0 |

| HR1-4 | 98 | 0.9 | 0.7 | 0.4 | 2.2 | 3.5 | 1.5-3.5 | 5.0-6.0 | 11.5-16.5 |

| HR1-5 | 98 | 0.9 | 0.7 | 0.4 | 2.2 | 3.5 | 2.0-4.0 | ≥6.0 | 44915 |

| HR1-6 | 98 | 0.8 | 0.6 | 0.4 | 2.5 | 4 | 1.5-2.5 | 3.0-4.0 | 5.5-8.5 |

| HR1-7 | 98 | 0.8 | 0.7 | 0.4 | 2.5 | 4 | 2.0-3.6 | 4.0-5.0 | 7.0-11.0 |

| HR1-8 | 98 | 0.9 | 0.7 | 0.4 | 2.2 | 3.5 | 2.6-4.0 | 5.0-6.0 | 11.5-14.5 |

| HR2-1 | 99.5 | 0.05 | 0.01 | 0.3 | 2.5 | 3.8 | 0.58-1.5 | ≤3.0 | 4.5-8.0 |

| HR2-2 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.8 | 0.9-3.0 | 3.0-5.0 | 5.5-12.0 |

| HR2-3 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.6 | 1.5-3.0 | 5.0-8.0 | 10.0-18.0 |

| HR2-4 | 99.5 | 0.1 | 0.05 | 0.3 | 2.5 | 3.6 | 0.9-3.0 | 3.0-8.0 | 5.5-18.0 |

| HR2-5 | 99.5 | 0.4 | 0.2 | 0.3 | 2.5 | 3.6 | 0.9-3.0 | 3.0-8.0 | 5.5-18.0 |

| HR2-6 | 99.5 | 0.05 | 0.01 | 0.4 | 2.5 | 3.8 | 0.5-1.0 | ≤2.0 | 3.0-5.0 |

| HR2-7 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.8 | 1.5-3.0 | 3.0-5.0 | 5.5-11 |

| HR2-8 | 99.5 | 0.05 | 0.01 | 0.2 | 2.5 | 3.6 | 2.0-3.5 | 5.0-8.0 | 10.0-15.0 |

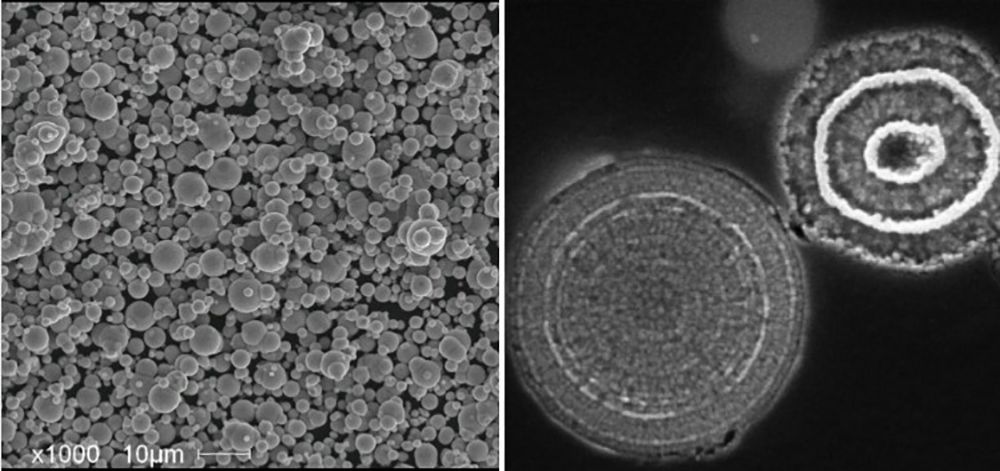

Sem

Uru

1.High chemical ịdị ọcha

2.Excellent electromagnetic Properties

3.Spherical

urughuru , yabasị akpụkpọ Ọdịdị

4.0.1-10 micron isi urughuru

5.High flowability, dispersibility na consisitency

6.Hgh ọrụ, comppressibility na magburu onwe sintering Njirimara