Cobalt Base Alloy welding Rods stellite rode prezzo

Nkọwa ngwaahịa

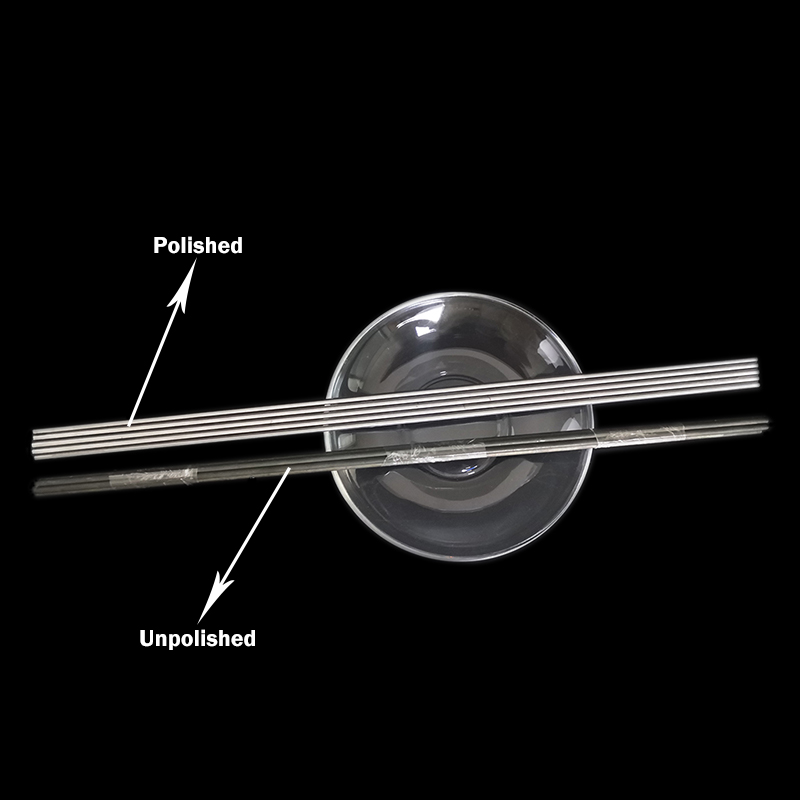

Tig Welding Co 1 6 Bar Cobalt Base Alloy Bare Rods

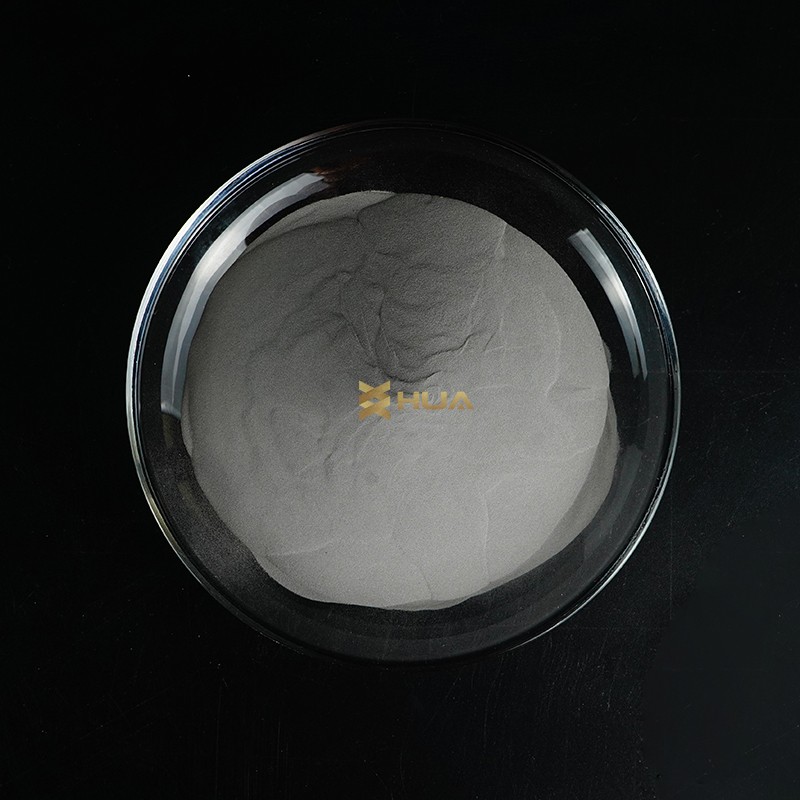

Mkpanaka Alloy Bare dabere na Cobalt:

- AWS RCoCr-C (HR CO1)

- AWS RCoCr-A (HR CO6)

- AWS RCoCr-B (HR CO12)

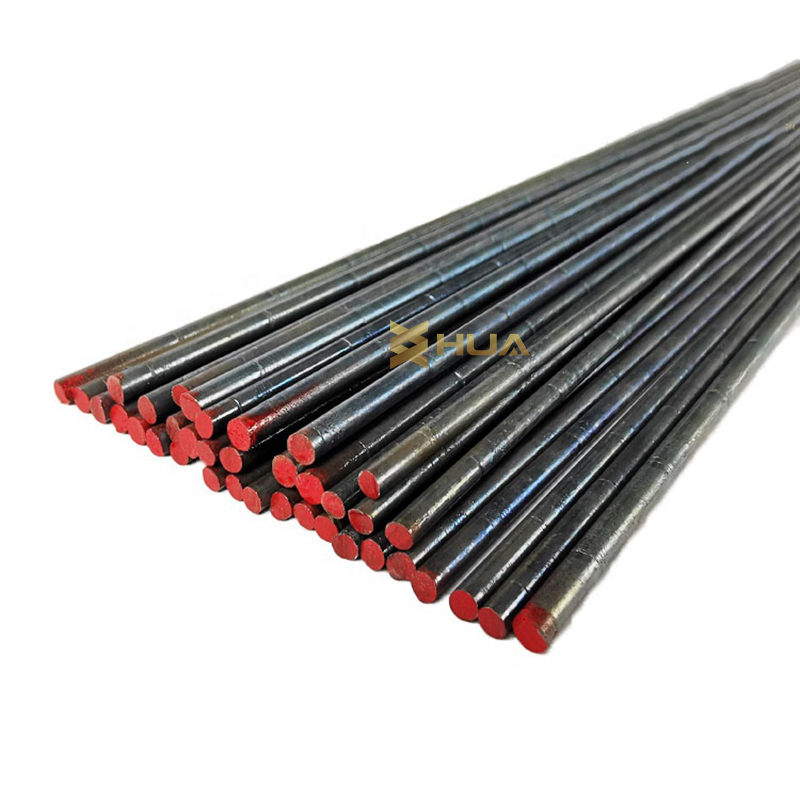

AWS RCoCr-C (1#)

Ọ nwere ọmarịcha iyi na nguzogide okpomọkụ na oke okpomọkụ.

Na-atụ aro iji na-eme valvụ akara ntinye, na-atụgharị akara mgbanaka, akuakuzinwo isi, cutter onu, wdg

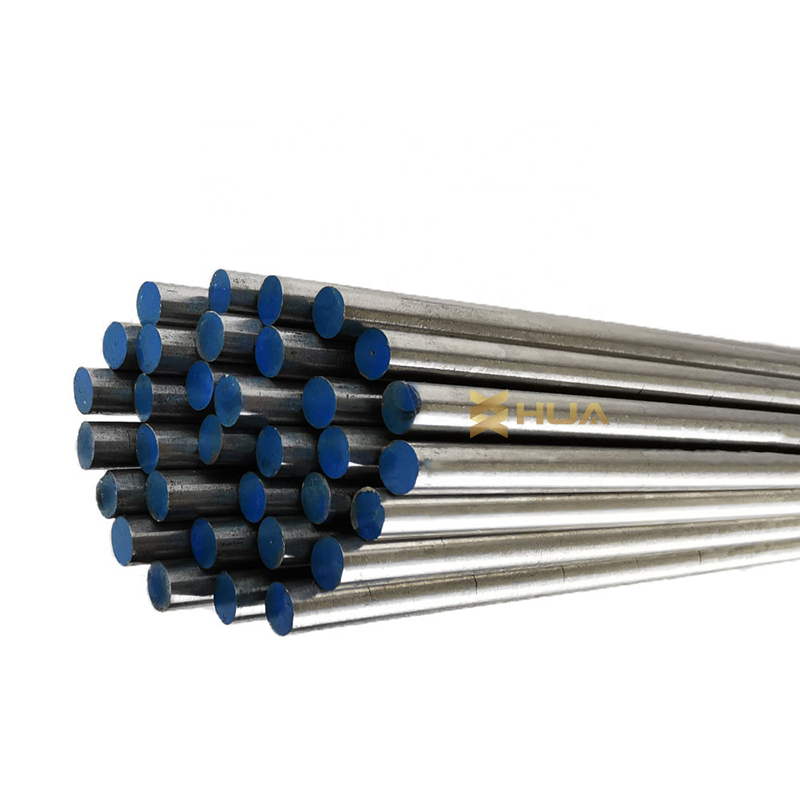

AWS RCoCr-A (6#)

Cobalt Alloy nke a na-ejikarị eme ihe na ihe eji arụ ọrụ dị mma na okpomọkụ dị iche iche, akwadoro iji mee ihe oche valvụ, akwa akwa akwa, valvụ dị elu, agụba turbine, wdg.

AWS RCoCr-B (12#)

Ọ nwere ezigbo nguzogide na oke okpomọkụ, corrosion na abrasion.Ejiri akwadoro maka ịme valvụ nrụgide dị elu, ihu ihu, sawteeth, wdg.

AWS RCoCr-B (#21)

Ọ nwere ezigbo nguzogide na oke okpomọkụ, corrosion na abrasion.Na-atụ aro iji na-eme fuild valvụ, brass nkedo anwụ, vlave oche, wdg.

Nkọwapụta

| NO | Ngwakọta kemịkalụ(%) | ||||||||

| C | Cr | Si | W | Ni | Fe | Mn | Mo | Co | |

| HR-DCo1 | 2.1 | 30 | 1 | 14 | ≤3.0 | ≤5.0 | ≤2.0 | ≤1.0 | Bal |

| HR-DCo6 | 1 | 30 | 1 | 4.6 | ≤3.0 | ≤5.0 | ≤2.0 | ≤1.0 | Bal |

| HR-DCo12 | 1.4 | 30 | 1 | 9 | ≤3.0 | ≤5.0 | ≤2.0 | ≤1.0 | Bal |

| HR-DCo21 | 0.2 | 28 | 1 | --- | ≤3.0 | ≤5.0 | ≤2.0 | 5.5 | Bal |

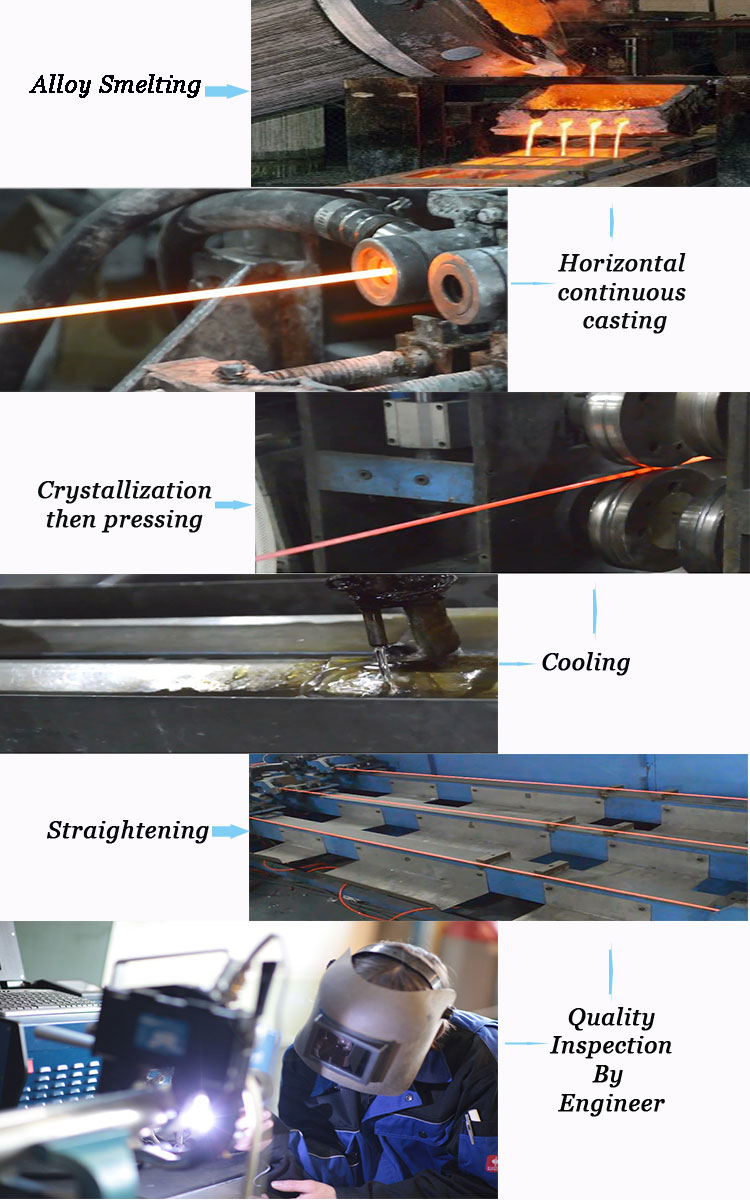

Usoro mmepụta

Ngwa

A na-eji ya maka oge ndị a chọrọ ịrụ ọrụ dị mma n'okpuru ọnọdụ nke iyi na nguzogide corrosion na okpomọkụ dị elu.Dị ka ụgbọ ala, valvụ injin combustion n'ime, okpomọkụ dị elu na valvụ nrụgide dị elu, eriri ọkụ na-ekpo ọkụ, mgbanaka ime na mpụta nke bearings, na-ekpo ọkụ na-anwụ anwụ, wdg.